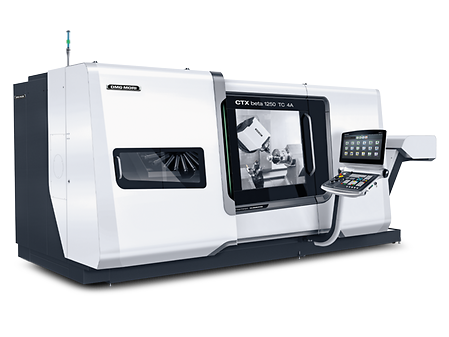

Dmg Mori Ctx Gamma 1250tc

Using development versions enables you touse the latest and greatest improvements to the project. Dmg emulator for windows. Development versions are released every time a developer makes a change toDolphin, several times every day!

Complex turning and milling operations with ultra-compact turning/milling spindle and up to 20,000 rpm

- Turning and milling spindle compactMASTER with 12,000 rpm, 22 kW and 120 Nm

- ± 100 mm Y-stroke for external machining

- Swivel range of B-axis ± 110° for maximum flexibility

Dmg Mori Ctx Gamma 1250 Tc 2

Tooling Supplier for the UK & Ireland. Monday-Thursday 8am-6pm & Friday 8am-5.30pm. CTX Gamma 1250TC - 2000TC. GMX 250, GMX 300, GMX 400. NLX 1500, NLX 2000, NLX 2500. A new concept to static and driven tooling for DMG Mori lathes by producing individual catalogue for all different DMG Mori models. Each catalogue contains all possible. CNC Lathe with Live Tooling Twin-Spindle Dual Turret & (HBM) Horizontal Boring Mill - Duration: 10:03. Gulf Coast Repair & Machine Shop 1,457,536 views. May 17, 2013 Turning, Profiling, Milling, Threading, Pockeing, Transfer to subspindle (min 7). DMG Mori CTX beta 1250 TC vs MAZAK Integrex i-300S Hello All, We are going to buy a new turn-mill machine and we are selecting between DMG Mori CTX beta 1250 TC vs MAZAK Integrex i-300S. Could you please send us your recomendation, advice, notes, experience. Turning, Profiling, Milling, Threading, Pockeing, Transfer to subspindle (min 7).

Tool magazine as a disk or chain magazine for shorter set-up and idle times

- Disk magazine for 24 tools in standard

- Chain magazine with 48 or 80 stations as option

- Tools up to 300 mm length and Ø 125 mm

6-sided complete machining by main spindle up to 700 Nm and optional counter spindle

- Integrated spindle drives with up to 700 Nm for maximum cutting performance

- Counter spindle with 6,000 rpm, 170 Nm and 51 mm bar capacity as option

Dmg Mori Ctx Gamma 1250 Tc Parts

The trend towards complete machining continues unbroken. On the one hand the diversity of products and variants is growing across a multitude of different branches and this in turn leads to a reduction in lot sizes on an increasingly wider scale. In view of such conditions, complete machining in a single setup quickly becomes the only economic alternative. On the other hand the workpieces are getting more and more complex while at the same time placing higher demand on precision. Added to this global competition is aggravating the earnings situation in manufacturing plants. DMG MORI has been revolutionising turn/mill complete machining with its turn & mill machines in the CTX TC series from their first appearance eight years ago. Meanwhile the second generation of these manufacturing all-rounders has arrived. With the CTX gamma 1250 TC and the CTX gamma 2000 TC DMG MORI will be presenting another two 2nd generation turn & mill centres at the EMO in Milan, both equipped with the new compactMASTER turn/mill spindle.

DMG MORI already produces the second generation of the smaller CTX beta TC series and now it is the turn of their larger sister machines, the CTX gamma 1250 TC and the CTX gamma 2000 TC, to follow in the footsteps of this development in time for the EMO 2015. The outstanding features of these two newly developed machines include a 150 mm longer X-travel of now 800 mm and the compactMASTER spindle in the B-axis – a cooperation project developed together with the Japanese engineers. Its 120 percent higher torque of 220 Nm in particular is a unique selling point.

With a diameter of 202 mm the length of the compactMASTER has been reduced by 70 mm so that it now measures only 450 mm – and all this with a 120 % higher torque. The interplay of the 150 mm larger X-axis (-25 / +775 mm) and the 20 mm longer Y-travel of ± 210 mm brings an enormous gain in freedom for users. It enables, for example, the radial machining of workpieces with maximum diameters of ø 700 with 170 mm long tools (with the B-axis in a vertical position). Where horizontal machining is concerned the 2nd generation of the CTX gamma TC has also gained in space: Workpieces measuring up to a good 300 mm can now be drilled out horizontally or hollow turned with no problem at all on the CTX gamma 1250 TC, while the CTX gamma 2000 TC is large enough for a tool length of 550 mm. The turning lengths of the CTX gamma 1250 TC and CTX gamma 2000 TC are 1,300 mm and 2,050 mm respectively.

The core element of both new CTX gamma TC models is still the B-axis with its swivel angle of ±120°, which is mounted on a highly stable travelling column and ensures milling performance in the field of 5-axis simultaneous machining. The machine concept has been radically revised with just such stability and precision in mind. The machines now have an integral thermal concept. This includes among other things integrated bed cooling as well as cooling of the linear guides of the travelling column, the spindle motors and the drive of the B-axis. Combined with the magnetic measuring system from MAGNESCALE the thermal displacement of the machine is now ≤ 10 µm. In addition DMG MORI has completely redesigned the travelling column. The U-shaped basic construction with 3+2 guide shoes in the Z-axis increases stability enormously, a feature that has a great impact on machining with the Y-axis. Linearity has been improved here by over 60 percent to now stand at ≤ 2 µm. Another indication of the innovative character of the machines is the up to 65 percent faster feed rate of 50 m/min in all axes. The machine can also be optionally equipped with a linear drive in the Z-axis, which with 1 g acceleration increases the feed to 60 m/min and ensures maximum long-term accuracy – including a 5-year warranty granted for the linear drive.

Internet explorer. You can add Firefox to your dock for easy access. Just open your Applications folder and drag Firefox to the dock.Firefox is now ready for use.